Posted by: Satterfield,Donald L.

Posted on: 10/20/09 09:48:40 AM

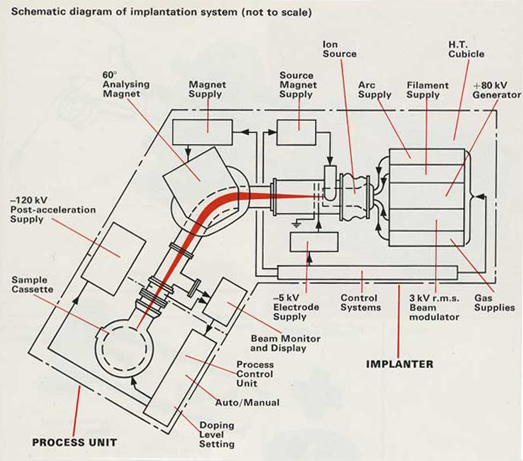

I work on the Lintott 200 KEV high current Ion Implanter at Signetics Corporation in Sunnyvale, Ca. Signetics had purchase one that no

one had been able to make work for any period of time.

Bob Parker was the manager of Signetics Ion Implant Department.We did all the Implanting for most of the Fabs.I was the Swing Shift Super-

visor over production,Equipment Engineering, Process Engineering,and work as a repair technician for swing shift.

We wanted to move the Lintott that set in Fab 11 over off Evelyn in Sunnyvale to the Ion Implant Department on Arques Ave. We were

bet by the Chairman of the Board that we couldn't get it to work. We took the bet. We not only moved the Lintott Ion Implanter, we used

very little vendor help doing so. We couldn't remove the High Voltage section in tact so we broke it down into pcs and moved it. They had

built the building around this Ion Implanter almost making it impossible to move it.

We moved it and put it back togethier on the new site. Then we had a Vendor Engineer check the machine for alignment etc and he could

not find a problem. He praised everyone in the moving and rebuilding of the Ion Implanter.

We qualified the implanter for production within a week after completing the install. The Ion Implanter was used to implant over 450,000

High Energy High Current Implants.over the next few years.Signetics would have spent $13-15 per Implant with outside implant Services or

around $6,000,000.

Later Bob Parker and I wrote a step by step operations manual for the Lintott that would let a absolutely new person operate the machine. We

were praised by the QC lady who had never operated the Ion Implanter and ran it like a professional using our operations manual.

We had the Lintott III version in Fab 15 at Signetics. They were built by Applied Materials Ion Implant Division. I work there for about a year

before coming to Signetics. I knew the machine very well. |