|

|

|

|

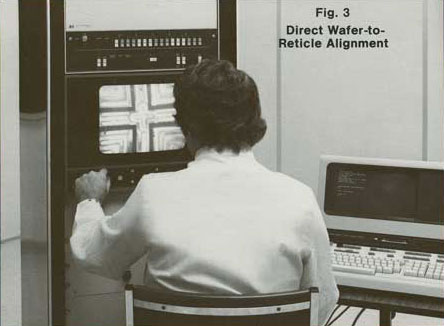

Don’t think ‘Single Lens Reflex’, instead think

‘Single Lens Repeater’ for that was what ‘SLR’ meant. Electromask’s

strongest rival, GCA, had already trademarked the popular concept of

‘Direct Step on Wafer’, and had pretty much corralled the term

‘wafer stepper’ as well, leaving Electromask with little room to

differentiate its stepper. And it was a good one too, in some ways

better than the GCA DSW, as the accompanying brochures show. But

Electromask, whose expertise was in mask making, was owned by TRE,

which didn’t understand how to market to the wafer fab industry, so

it was eventually sold out to a new startup, ASET (American

Semiconductor Equipment).

|